Duplex Stainless Steel 2507 (S32750) Plate Sheet in China

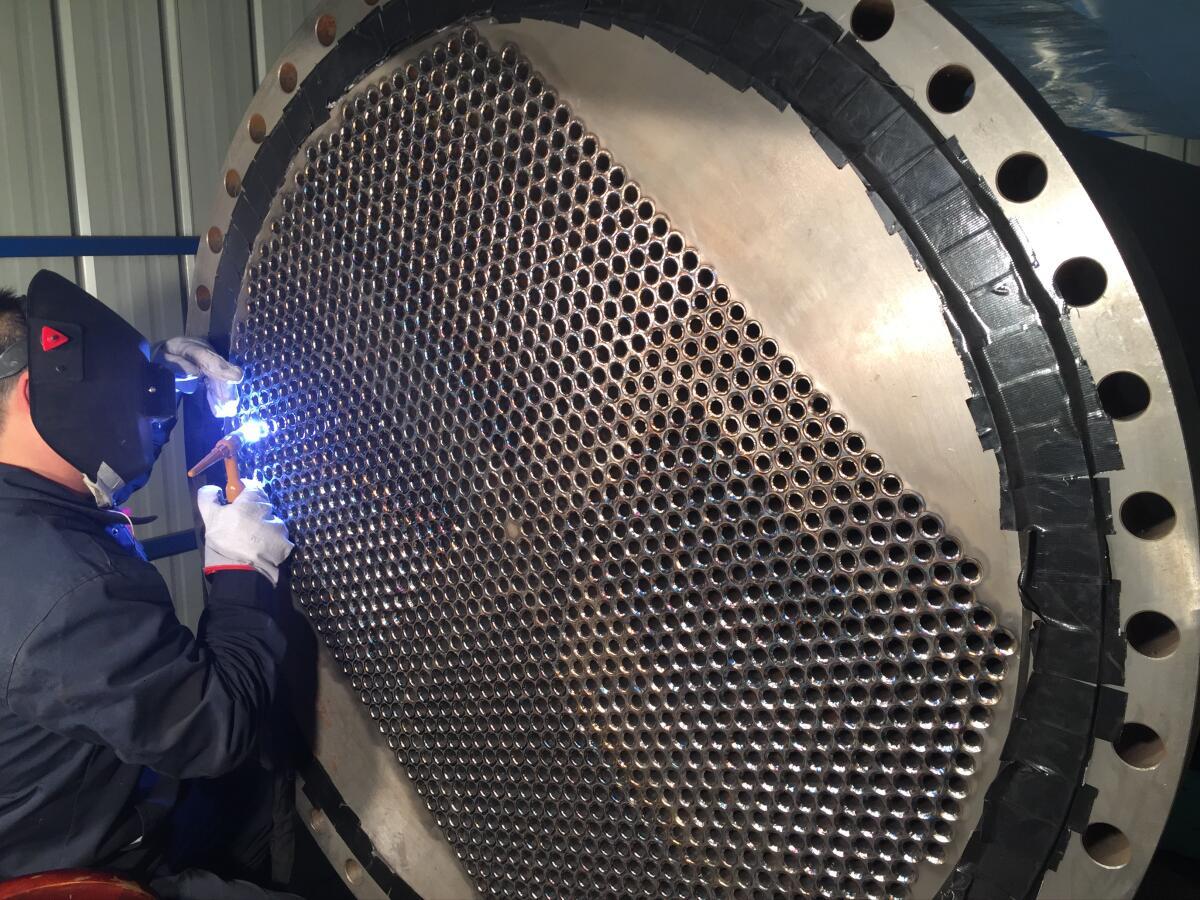

Suitable for petrochemical equipment, seawater desalination equipment, pulp and paper industry, chemical ships

Keywords:

Description

2507 is a ferritic austenitic (duplex) stainless steel that combines the most beneficial properties of many ferritic and austenitic steels, due to its high chromium and molybdenum content,

Therefore, it has excellent resistance to point corrosion, crevice corrosion, and uniform corrosion

Ability to corrode:

1) High chromium and molybdenum content → excellent resistance to spot corrosion, crevice corrosion, and uniform corrosion

2) Dual phase microstructure → high resistance to stress corrosion cracking

3) The mechanical strength is very high.

Chemical composition

| unit:(wt%) | |||||||||||

| specifications | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | PREN |

| ASTM2507 | ≦0.03 | ≦0.8 | ≦1.2 | ≦0.035 | ≦0.02 | 24~26 | 6.0~8.0 | 3.0~5.0 | ≦0.5 | 0.24~0.32 | ≧41 |

| longpeng2507 | 0.02 | 0.55 | 0.9 | 0.022 | 0.001 | 25.63 | 6.24 | 3.59 | 0.28 | 0.27 | |

| *PREN = Cr+3.3Mo+16N | |||||||||||

2507 has superior Cl - corrosion resistance and excellent corrosion resistance in non oxidizing acid environments

Mechanical properties

| Distinguish | Yielding strength 0.2%(MDa) | Tensile strength (Mpa) | Elongation A50(%) | Hardness (HB) |

| ASTM2507 | ≥550 | ≥795 | ≥15 | ≤330 |

| Representative value | 600 | 900 | 33 | 270 |

Pitting resistance performance

| average value | |||

| distinguish | medium | Base material | |

| longpeng | Other societies | ||

| CPT (G150) | 1MNaCI | >80℃ | >80℃ |

| CPT (G48A) | 6%FeCl3 | 70℃ | 70℃ |

| CPT (G48E) | 6%FeCl2+1%HCI | 80℃ | 80℃ |

| CPT (G48F) | 35℃ | 35℃ | |

Stress corrosion cracking resistance

| distinguish | medium | longpeng | Other societies |

| SCC Sensibility | 42% MgCl2(Boiling) | ≦0.075 | ≦0.085 |

Harmful metal interphase

| Experimental standards | medium | Benchmark allowable range | longpeng |

| A923C | 6%FeCl3,PH 1.3,50℃,24hr | ≤10mdd | 3.3mdd |

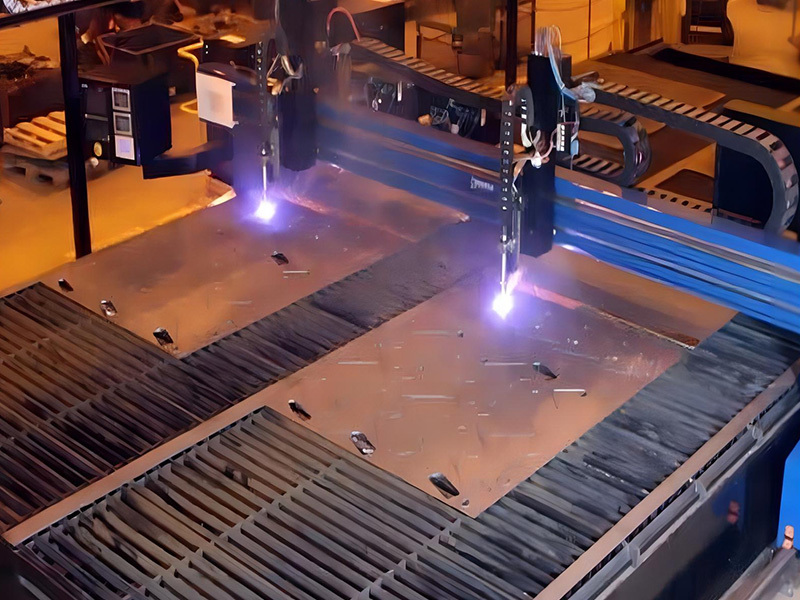

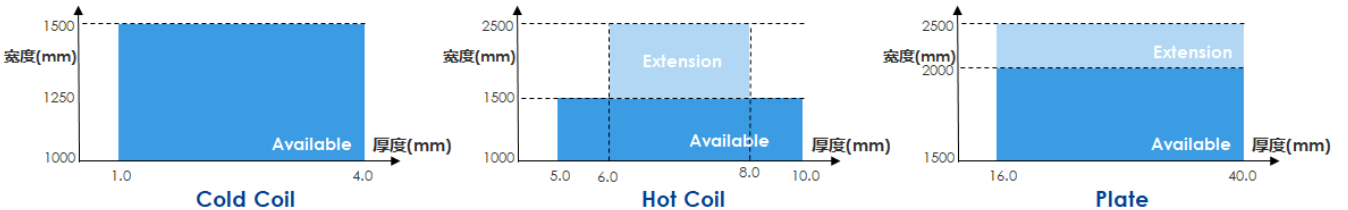

Production specifications

1.<1.5mmt products require secondary rolling, with a delivery time of 60 days

2. Backward 6t/8t * 2.0M test; 2.5M plate

Scope of application

Applicable Uses

petrochemical industry

Desalination of seawater

Pulp and paper making

Flue gas desulfurization

Chemical ships, etc

Product Advantage

1) Extremely excellent corrosion resistance

2) Critical pitting temperature>80 ℃, reaching the leading level in China

undefined

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!