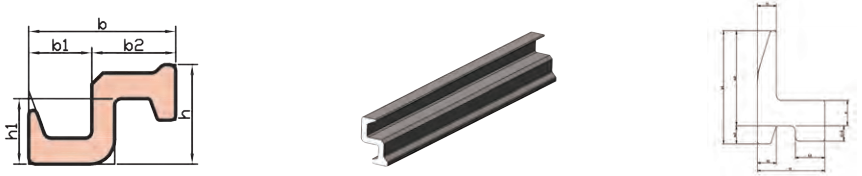

forklift mast profiles section channels MAST RAIL handling equipment

Longpeng steel has the stronger ability to develop forklift channel steel. More than 40 models have been successful developed, and the product quality has been recognized by customers.

Keywords:

Forklift profiles

Description

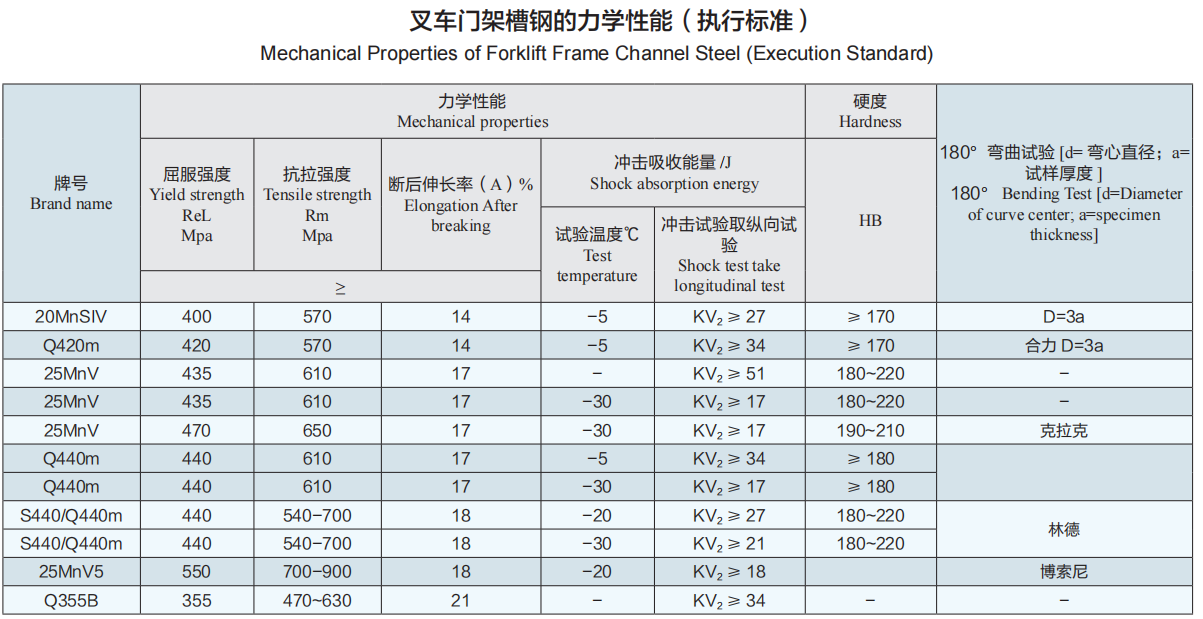

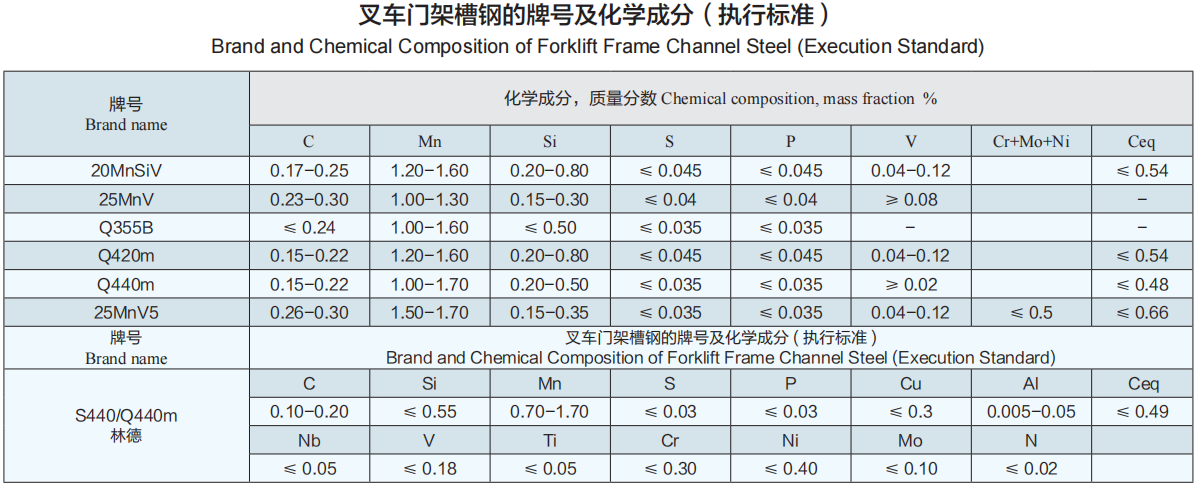

Longpeng Steel boasts a formidable capacity in developing forklift channel steel. So far, we have successfully launched over 40 models, with our product quality widely acknowledged by customers. This achievement underscores our commitment to excellence and dedication to meeting the industry's diverse needs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

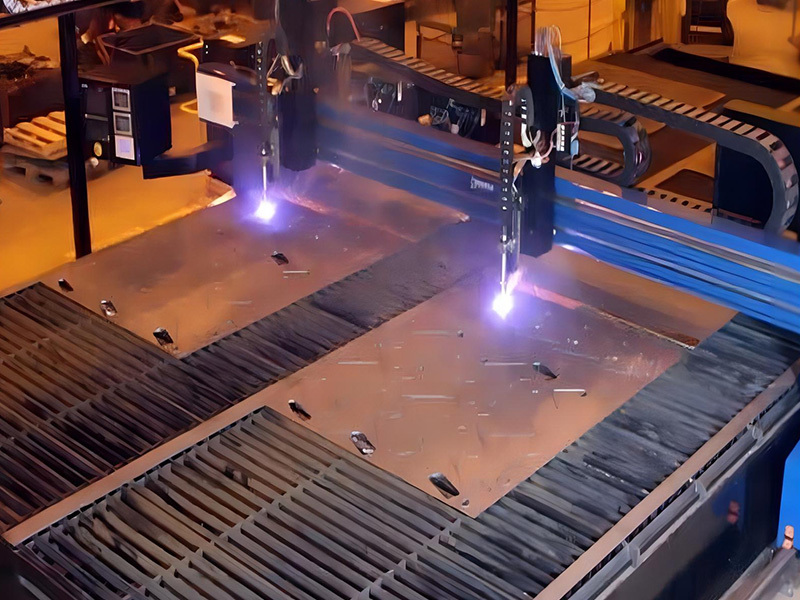

Advance Equipment

Longpeng steel has the stronger ability to develop forklift channel steel. Currently, more than 40

models have been successful developed, and the product quality has been recognized by customers.

With the continuous improvement of hot-rolled forklift channel steel market, more and more customers put forward higher requirements, hoping we can produce forklift mast assemblies for customers to reduce the manufacturing cost of forklifts.In 2017, we started to build a complete forklift mast assembly production line with automated processes such as mechanical processing, robotic welding, painting, and assemble .Currently, forklift mast assemblies are mass-produced and exported to foreign markets such as South Korea and Turkey

Robot welding is capable of meeting the precision requirements of forklift mast assemblies. By utilizing precision robotics, welding processes can be executed with utmost accuracy, ensuring that each mast is fabricated to exact specifications, enhancing both safety and performance.

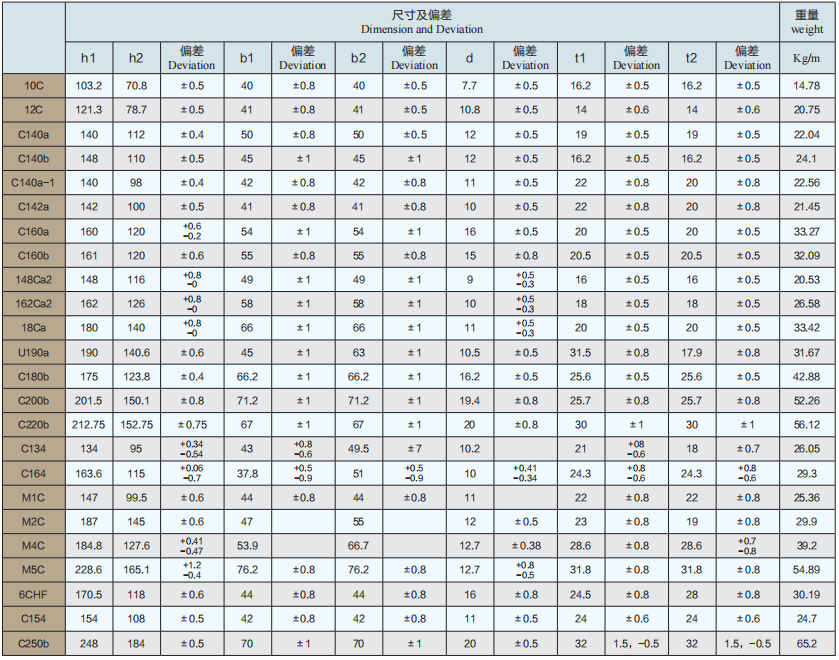

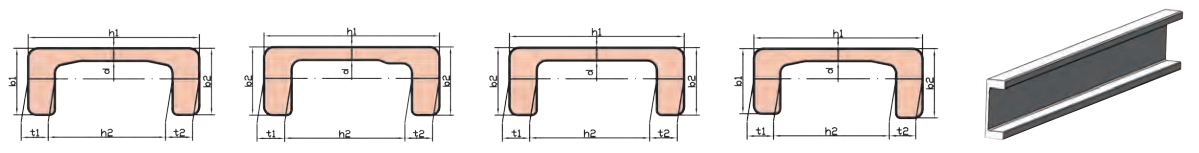

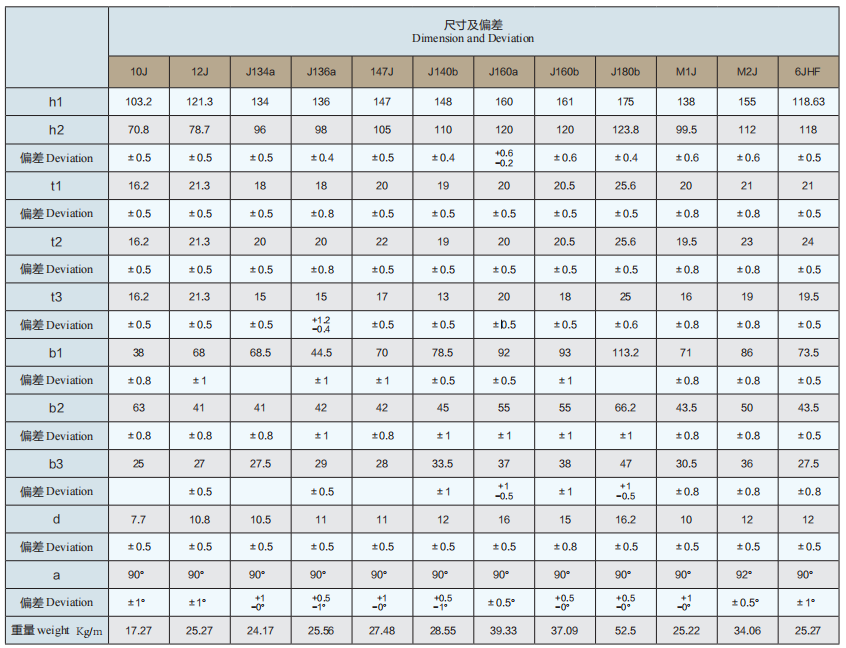

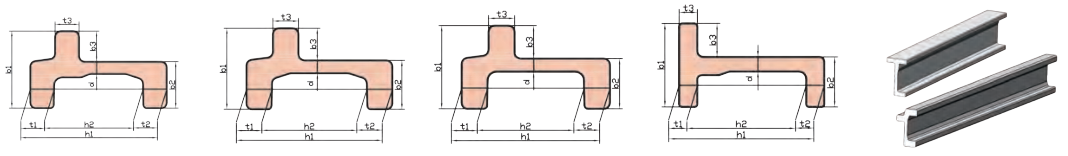

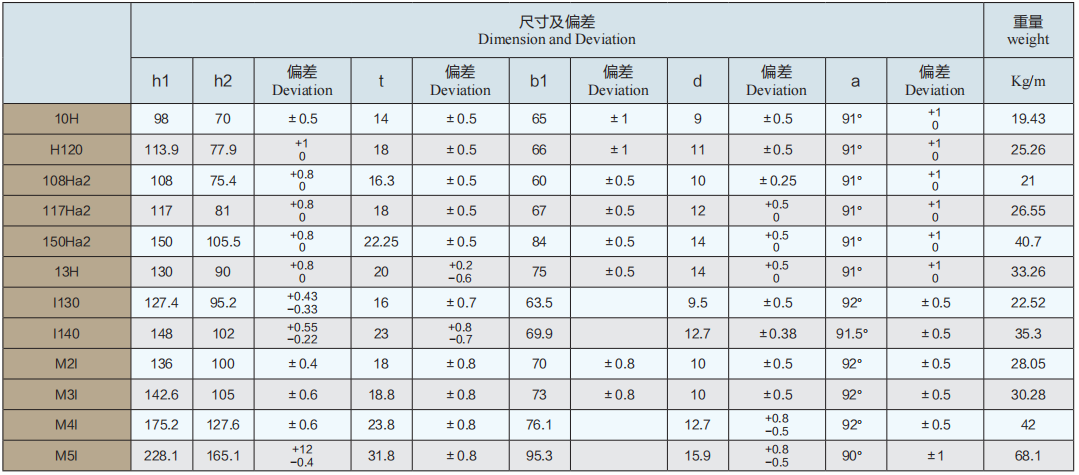

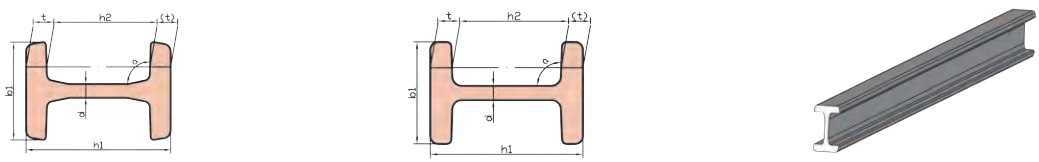

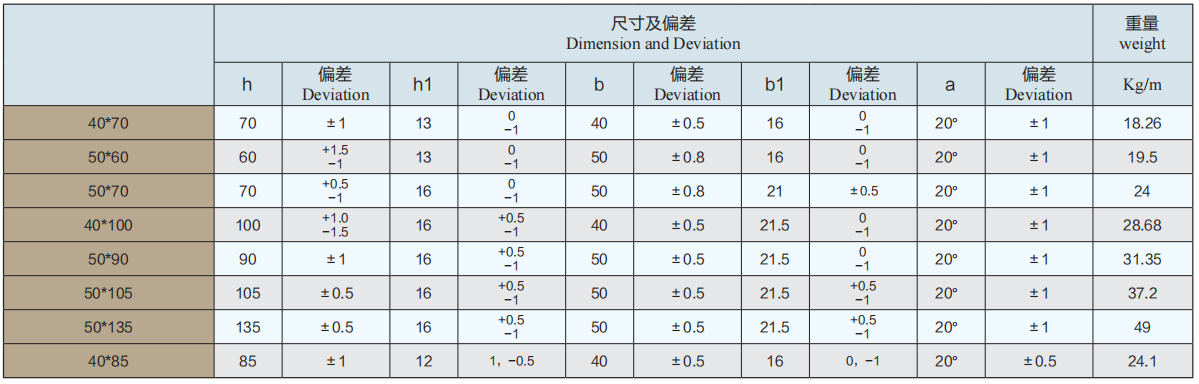

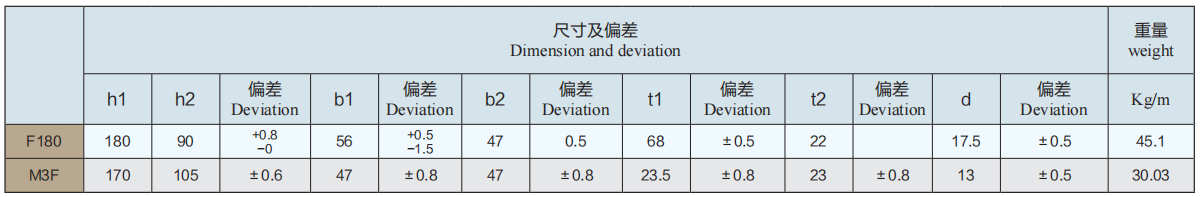

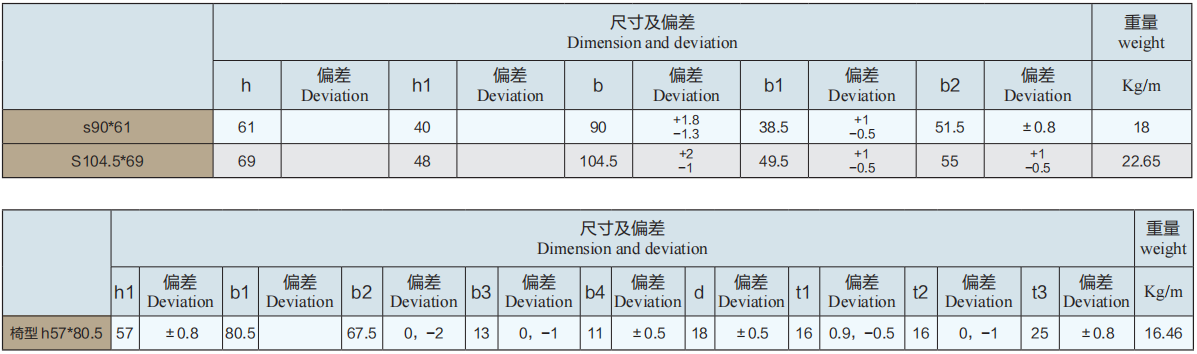

We are now able to offer a diverse range of beams, including C beam, H beam, J beam, S beam, and Carriage beam. This comprehensive selection ensures that we can fulfill our customers' varying needs, delivering tailored solutions that meet their specific requirements.

Advanced testing equipment is the cornerstone of quality assurance. By leveraging state-of-the-art technology, we ensure that every product meets the highest standards of precision and reliability. This commitment to excellence allows us to deliver superior quality products to our customers, exceeding their expectations and ensuring their satisfaction.

Our company is equipped with an advanced spraying production line, which ensures the high quality and efficiency of coating processes. This state-of-the-art facility allows us to meet various coating needs, delivering superior results that satisfy our customers' expectations.

Based on the drawings provided by customers, we also offer a service for fabricating forklift mast assemblies

Sufficient inventory is a crucial guarantee for prompt delivery

Our well-stocked inventory guarantees the fastest possible delivery, meeting your needs prompt and efficient

We are capable of cutting our products according to customers' specific requirements, fulfilling any length demand with precision.

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!